Background Info

To lift marshmellows and move them away from the assembly line to be disposed of, a robot arm is nessasary to accomplish such a task.

Mechanical Design

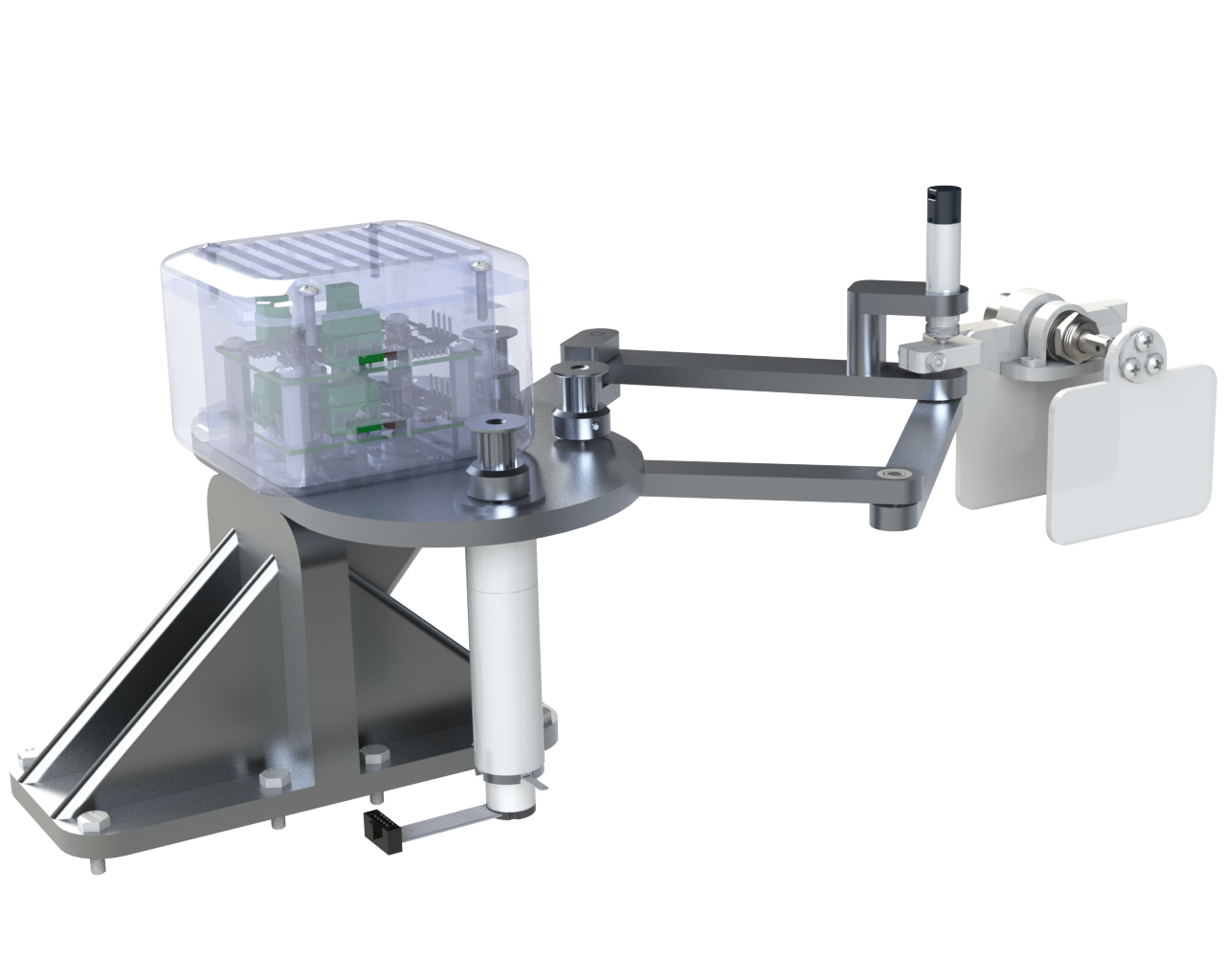

We have developed a parallel-arm, three-and-a-half-degree freedom, marshmallow disposing robot. The robot’s arms and wrist are powered by three Maxon motors, and the gripper is actuated by a linear solenoid actuator. The low weight and inertia of this design have made sub-second cycle times possible. The model is created in SolidWorks and showcased using SolidWorks Visualize.

Stress analysis is done on the system to ensure it can handle the load from the chosen motors and the weight of the system. Since the von Mises theoretical stress does not exceed the material yield strength, it demonstrates our practical and feasible design.

Significance and Contributions

I was in charge of the entire mechanical design as seen here, while my teammates worked on the control system and the electronics respectively. Compared to traditional Selective Compliance Assembly Robot Arms (SCARAs), this prototype has significantly decreased moment of inertia, and faster response times to be used within the industrial setting. The contraption is also lightweight and cheap due to its small footprint, all made with easy to manufacture materials.